The NMT (Non-invasive Micro-test System) can measure ion concentrations down to picomolar levels but must be measured slowly at approximately 1-2 seconds per point. This is mainly due to the mechanical disturbance of the gradient by the electrode movement, although the time constant of the LIX (Liquid Ion Exchanger) electrodes is also a factor. It takes a fraction of a second to reestablish the gradient. The electrode is stepped from one position to another in a defined sampling routine while also being scanned with the 3D micro-stepper motor manipulator (CMC-4). 1,2,3D or complex measurement paths are user programmable.

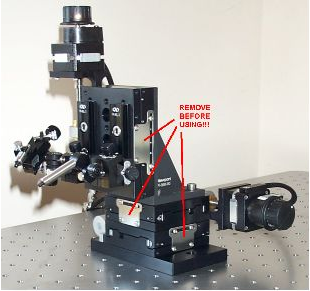

A complete BIO-IM system contains:

YG-SP: The Signal processor includes an Ion Amplifier and two ion-selective headstage.

2HM-1: 2 head mounting assembly with 3D manual micromanipulator for simultaneous two electrode measurements

IEMS-1: Ion electrode making station

Ion Electrode Kit: 2 Teflon electrode holders, dri-ref. electrode

FC: Faraday cage, to cover the experimental area due to the high resistance of ion selective electrodes and the gain of the electronics.

RP: Research Platform, it contains:

Computer Motion Control System (YG-CMC4)

Inverted Biological Microscope (Objective lens: 10-40 X)

Computer with 320+GB hard drive, 2+GB RAM and 3 PCI slots for National Instruments DAQ cards (PCI-6229 data acquisition, PCI-1405 image acquisition, PCI-7334 motion control).

The imFlux Software for Windows

Video capture system includes color video monitor and CCD video camera

Vibration Isolation table

Specifications

The equipment platform and software provide a multi-use data collection system for research and commercial assays. It utilizes a programmable 3D micro-positioning system, a real time data collection system and a video microscopy system. Variability of use, low cost, and user friendliness are the prime concerns in the development process. This platform is designed to grow with the user and remain useable for a long period of time. Other commercially available devices such as potentiostats, voltage or patch clamps can be integrated into the platform without software changes, although custom programming can be provided.

YG-SP: Specification as follows:

Main Amplifier: Input Power: 100-240 VAC 50/60 Hz

Amplifier Gain: x10/x100 standard

Bandwidth: 10 Hz standard

Two channels for simultaneous dual measurements

Ion-Selective Input resistance: 10 TΩ minimum

Headstage: Gain: x10

YG-CMC contains the 3D Stepper Motor Translator and the Motion Controller

The Computer Motion Control system was custom designed for use with all of our measurement systems and the imFlux software program. It relies on the large memory and high processing speed of a host computer to generate step pulses and direction signals that are sent to a driver/interface module through a standard PC parallel printer (LPT) port. The driver/interface modules translate step pulses and direction logic into signals that drive the stepper motors on the motorized 3D micro-positioning stage.

The motion control system is controlled by a compatible PC. Three of the axes (X, Y, Z) are used to drive the 3D Motorized Manipulator.

The computer provides step, direction, speed and steps/micron logic.

The computer also provides positional information. Though this system was primarily designed for positioning a microelectrode it has many other applications as well.

Front panel of Motion Controller:

The minimum micro-step move is 49 nm. The system has an accuracy and repeatability of approximately 0.5 micrometers. The following specifications are listed for you:

Motorized Drives

Travel: 1.25"/ 2.00" (30 mm / 50 mm)

Speed: Up to 2 mm/sec no load

Positioning Accuracy: ~ 0.2% of travel

Bi-directional Repeatability: ~ 1.0 micron

Minimum Incremental Motion: 0.003 to 0.8 µm

Translator Stages

Angular Deviation: ~ 200 mrad

Centered Load Capacity: 35 / 47 lb (16/19kg)

Vertical Load Capacity: 15 lb (6.8 kg)

Threaded holes: 1/4-20 on 1" centers or M6x1.0 on 25mm centers

Three acceleration profiles are supported.

They are best described with the following graphs:

Producing Area:USA